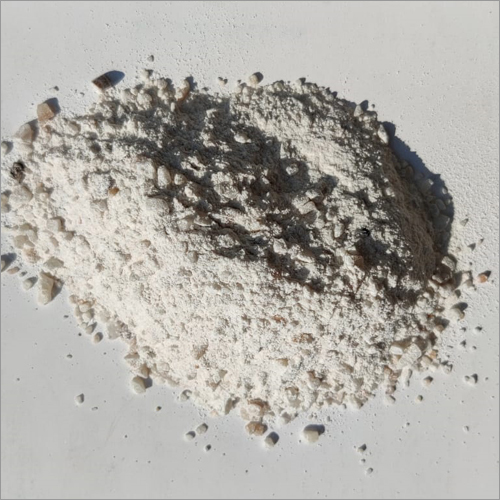

About Silica Ramming Mass

Silica Ramming Mass is used for lining purpose in steel melting induction furnaces . The material is made of 100% quartzite stone. Due to its property of high melting point the lining of quartzite based ramming mass acts as a wall between liquid hot steel and furnace wall. Quartzite is more suitable for ramming mass in comparison to quartz as it has more bulk density,refractoriness and melting point.Superior Application for Induction Furnace LiningsSilica Ramming Mass is expertly crafted for induction furnace lining in steel casting operations. Its high purity minimises contamination and ensures the integrity of metal production. The customizable grain sizes allow precise matching with furnace specifications, ensuring optimal performance and thermal stability during use.

Reliable Quality and Thermal PropertiesWith SiO2 content over 99%, minimal iron oxide, and excellent refractoriness up to 1720C, Silica Ramming Mass is trusted for its consistent quality and performance. It is physically stable with low moisture, providing secure and durable furnace linings that withstand high temperatures and demanding industrial environments.

Flexible Packaging & Delivery OptionsSupplied in HDPE or jumbo bags, Silica Ramming Mass is available in 25 kg, 50 kg, and 1 MT sizes to suit different scales of operations. Producers, exporters, and suppliers across India can reliably deliver the material in packaging that ensures protection and convenience during storage, handling, and transportation.

FAQ's of Silica Ramming Mass:

Q: How is Silica Ramming Mass used in induction furnace lining?

A: Silica Ramming Mass is packed into the inner lining of induction furnaces where it forms a strong, heat-resistant barrier. This protects the furnace and the molten metal from contamination, ensuring clean casting processes in steel production.

Q: What are the major benefits of using Silica Ramming Mass in steel casting?

A: Its high purity SiO2 content, low iron oxide, and excellent thermal stability minimise metal contamination and prolong furnace life. These properties result in better quality steel and reduced maintenance costs for induction furnaces.

Q: What are the available grain sizes for Silica Ramming Mass and why does it matter?

A: The material is offered in 0-5 mm, 0-2 mm, and customizable grain sizes. Proper grain selection ensures uniform lining and optimal packing density, vital for effective heat transfer and mechanical stability in furnace operations.

Q: How is Silica Ramming Mass packaged for delivery and storage?

A: Silica Ramming Mass is packed in HDPE bags or jumbo bags, available in 25 kg, 50 kg, and 1 MT options. This packaging protects against moisture and physical damage, facilitating safe transportation and storage.

Q: When should Silica Ramming Mass be replaced in an induction furnace?

A: Replacement depends on the frequency of furnace usage and the wear rate. It is generally replaced after each production cycle or when the lining shows signs of erosion, cracks, or contamination, ensuring safe continued operation.

Q: Where is Silica Ramming Mass primarily sourced and distributed in India?

A: This product is manufactured and distributed by various suppliers, manufacturers, exporters, and traders throughout India, allowing easy procurement for steel plants and foundries across the country.

Q: What process ensures the high purity and stability of Silica Ramming Mass?

A: The ramming mass undergoes strict selection and processing where impurities are minimized, controlling Fe2O3, CaO, and MgO levels. Customized sizing and controlled moisture content guarantee a high-performance, stable refractory lining.